POST HARVEST FOOD LOSS AND FOOD SECURITY A GLOBAL CHALLENGE

In most of the cases, simple and cost effective interventions for post harvest handling, storage ,grading sorting and processing infrastructure can enable farmers and processors to reduce food losses and substantially increase their realisable value of the crops. This adds to a significant improvement of food security in the respective countries, aligning to the Sustainable Development Goals (SDG), Agenda 2030 established by the United Nations in 2015 .

Our company is committed to work for small-medium scale food producers to enable them to double their productivity and income as per Target 2.3 of SDG 2, Agenda 2030 of United Nations.

MISSION STATEMENT

Bajaj Processpack Limited was incorporated to develop and manufacture reliable and cost effective plant and machinery across farm-to-fork value chain to add value and reduce post harvest food wastage, designed for the small and medium sector requirements in the developing countries worldwide.

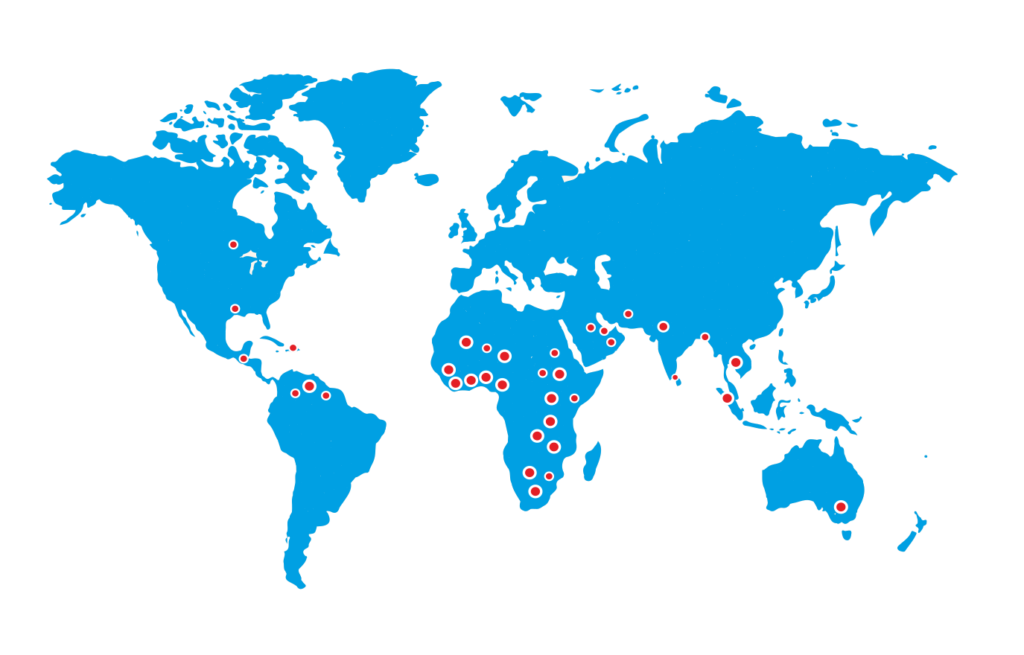

BEST SUITED FOR DEVELOPING COUNTRIES WORLDWIDE

The company’s design philosophy is to build sturdy, efficient, and reliable plants and machinery that are technologically suited to be operated and maintained by semi / unskilled workforce in developing countries in Asia, Africa, Carribean and Latin American regions.

Turnkey projects for multiple food segments

Turnkey projects for multiple food segments

Primary Processing of Fruits and Vegetables

For washing, sorting, grading, waxing, packing and storage Biomass / solar powered cold rooms that can be set up in farms and fruit growing offgrid areas.

Secondary Processing and Packaging of Fruits and Vegetables

Fruits and vegetable processing into pulp, puree, paste, concentrates, jams, juices, sauces, frozen and dehydrated products and packaged in cans/bottles/ aseptic pouch packaging.

Beverage Processing and Packaging

For packaged drinking water, juice beverages and carbonated beverages etc. with packaging options in glass/PET bottles, aseptic packaging, pouches etc.

Milk/Dairy and Sweets Processing

For pasturised/UHT/flavoured milk, yoghurt, cheese, ice cream, milk based sweets and end-packaging in cans, bottles and pouches.

Central kitchens for educational / religious / industrial organizations

For processing rice, vegetables & cereals into ready-to-eat meals.

Renewable Energy Technologies Division

Strengthening the Key pillar of developing economies

Premium Quality Machines

Presenting premium quality array of food and Fruit Processing Machines for FMCG needs

Latest Technology

Machines designed with Latest Technology to achieve best quality at less time

Maintenance & Repair

We make sure that your machines gets Maintenance & Repair services timely

24/7 Support Staff

Our staff will help you whether you selecting machines or any breakdown of machines

In Best Prices

We make sure to give you best deal for the best product in the best Market prices

On Time Delivery

Our staff will always be on time with your selected machine at yur doorstep

Our Global Footprint

Our Valuable Clients

Our Leading Clients

Client Testimonials